Cutting edge nanotechnologies are one of the key technologies present in material synthesis as well as material analysis. They are used in production of advanced metal parts for high tech sectors like aviation and space sector. Another, seemingly less fascinating field, but widely used in many high-performance materials is manufacturing of additives. One of the first so called Proof-of-Concept results of the NANO-REGION project, financed by the Program Interreg V-A Italy-Slovenia 2014-2020, focused on research of an advanced aluminium alloy composition, the ever-present fight against metal corrosion and success of newly developed approaches in the formation of the protective film.

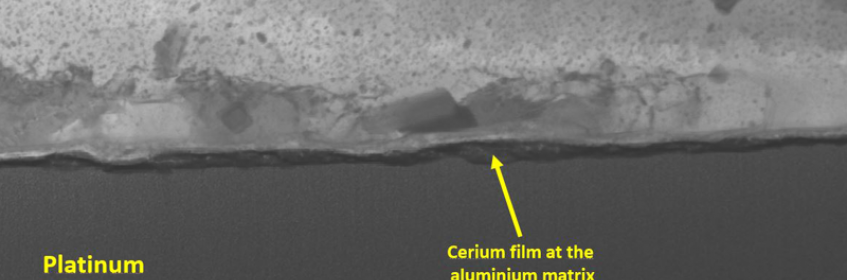

An aluminium alloy sample, send to one of the labs in the NANO-REGION project network, was in the first step analysed with scanning electron microscope. Microstructural characterisation confirmed presence of iron and copper-rich intermetallics, which gives us insight into the affect they can have on the performance of the alloy.

With the giant leap in progress that metals brought human society, a destructive force called corrosion was unleashed and started its determined and vigorous plague. But not only to humanity, to environment as well, since from the early civilizations, generations used antifouling paints and many other anti-corrosion chemicals that are today recognised as harmful. One of the environmentally friendly approaches to protect alloys in the industries, where the highest performance is a must, is use of different cerium salts which can form an inhibition film to protect the alloy. Within the study, carried out in the frame of the NANO-REGION project, alloys with and without cerium salts were exposed to 6h of immersion in the corrosive media. All cerium salts proved to be successful in creating a protection barrier and the best performing salt is a candidate with a possibility to travel to space!